CRAFTSMANSHIP

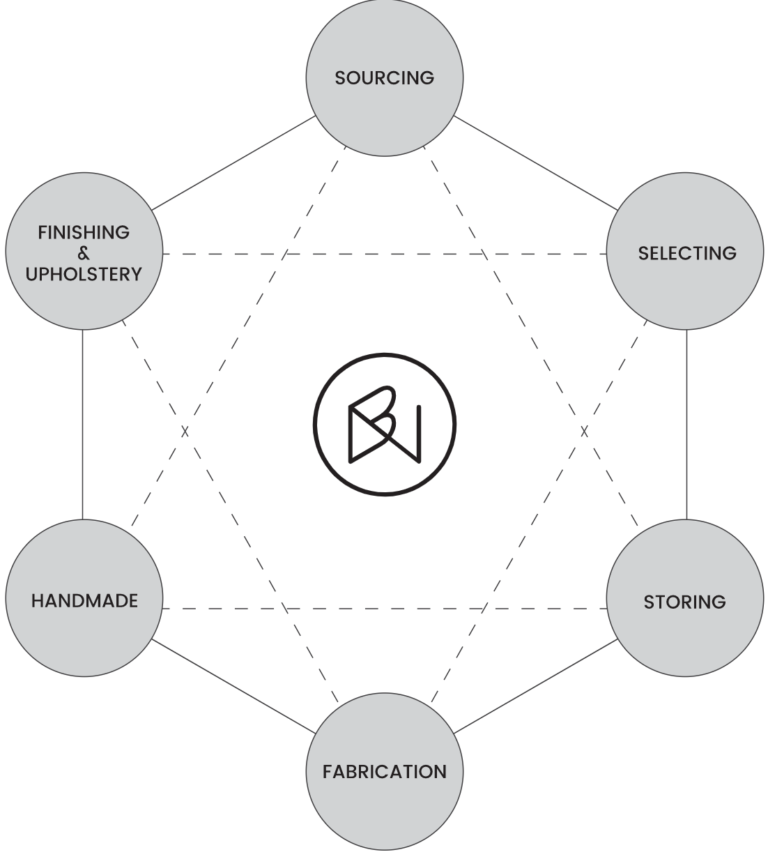

Craftsmanship Value Chain

SOURCING

The wood we use for our projects are sourced from sustainable forest globally. With more than 20 years of restoration work and global projects, we have developed a wide network of suppliers, millers, lumberyards and timber traders that are able to provide high quality wood. Today, we are still able to source Burmese teak from traders that have stockpiled before the logging ban in Myanmar in April 2014. Burmese teak offers richer timbre coloration; and due to its age, the grain is tighter and more pronounced.

SELECTING

Our huge network enables us to choose the best lumber for each project. This ensures that we are not limited to the size and scale of each piece of furniture. The size of the pieces of lumber is important to cater to the wide variety of furniture that we manufacture. Apart from the size, the quality of the wood is also dependent on the age and species of the trees. Trees like teak and other tropical hardwood are chosen because of their durability, high tensile strength, colour and beauty of their tight grain.

STORING

FABRICATION

Each design is special, and the selection of the right piece of wood is essential in ensuring the lasting beauty and durability of each of our furniture. The choice of wood is often decided between the artisan and the client; after which, the artisan will draw on the piece of chosen wood the template of the furniture in question. After each element of the furniture is drawn on the piece of wood, each piece is hand-sawed to ensure accuracy.

HANDMADE

FINISHING & UPHOLSTERY